Recycling glass is one of the many ways we can help reduce pollution and waste. Instead of letting landfills pile up with glass which threatens our environment, there are ways we can reuse this glass. The publisher of the Hellenic News of America, Aphrodite Kotrotsios, hosted Maria Mendorou, Director of Business Development and Outreach at Pace Glass Recycling on her show, ‘Live with Aphrodite’, which was streamed live on Instagram. Aphrodite and Maria discussed the impact COVID-19 has had on the recycling industry, the importance of glass recycling and Pace Glass’ glass innovative technology. Pace Glass is a technologically driven glass recycling company that is able to recover mixed glass from household waste found in land-fills and remake that glass into common household and industrial products. Pace Glass was co-founded by Steve and George Valiotis along with Michael Mahoney in 2013 and is located in Jersey City.

Describe Pace Glass’ mission and the innovation behind your technology.

We take glass from household and commercial waste-streams, and produce cullet – pieces of glass that can be reused by basically anyone in the glass making industry to save the cost of their production and do their part in saving the earth.

What makes what you do stand out/what is unique about your process?

The first that deserves mention is our ability to turn all types of waste into energy. This includes glass AND other recyclable commodities, such as ferrous and non-ferrous metals, paper, and even topsoil. When investing in proper technology, waste turned into energy mitigates climate change. By producing energy from waste, we reduce CO2 emissions, lessen the emissions of trucking waste to landfills, and reduce the overall size of landfills; thus protecting the use of more land for waste storage.

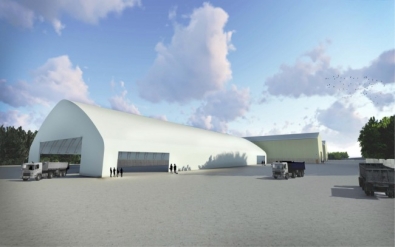

Secondly, the physical production of the plant. Our plant in Andover will be the largest and most technologically advanced glass recycling plant in the United States. Scheduled to produce 750,000 tons of cullet annually, it will produce an unmatched quality in cullet that is much desired by the end-markets that are looking to use recycled glass, in an effort to lower their own production costs.

With a unique mix of professional youth and old age wisdom, the variables of our team ensure the growth of our company. Our operations team is a group of exceptionally driven professionals that share the same vision for the industry and Pace Glass Recycling, which communicates weekly about the progress and direction of that vision. Everyone, from the leaders of the Board to the manager of our on-site facilities are very hands-on and communicate regularly about their departments.

What difficulties does glass recycling face, and how are you tackling it?

Since China’s bans, municipal programs are no longer accepting certain types of waste that was once considered recyclable. At the same time, the price of recycled material is commodity based. Landfills are thus filling at a dangerous pace, and municipal programs are finding themselves overwhelmed with problems of sustainability. Glass, in particular, plays a major role in this.

On problem that glass faces is contamination, which sends tons of glass to landfills. You realize how devastating that is when you learn that it can take 1 million years for glass to decompose.

To tackle, PACE Glass Recycling invested heavily in the technology of our plant, so that we can take any glass, particularly glass from municipal recycling facilities (which tends to be extremely contaminated and difficult to recycle), which is unprecedented in the industry within the United States. Even more amazing is the fact that, from that glass, we create an unmatched quality and consistency in cullet that is highly desired by the end-market.

What impact has the Coronavirus had on the waste and recycling industry?

The recycling industry is adjusting itself to the changes of where waste is being accumulated. Trucks are having to change their routing from corporate addresses to residential ones, as their staffs are running the business from their homes in practice of social distancing.

The novel coronavirus, as terrifying as it has presented itself, is actually bringing out long- forgotten traits that we all have. I am referring particularly to self-sufficiency and preservation – both of which recycling is a prominent characteristic.

How has the Coronavirus outbreak helped to reduce emissions?

The need to practice self-sufficiency and preservation during the outbreak, has led to an increase of recycling. In doing so, you’re cutting the costs within your own home. The positive effects, however, trickle into the environment.

By recycling, you’re supporting a decrease in land-fills and incinerator fumes emitted during the burning of landfilled garbage.

Additionally, as mentioned earlier, pollution will certainly decrease during the Covid-19 outbreak. China, among other countries, is already experiencing such changes. This one of the balancing effects and even positive consequence that has sprouted from such an unfortunate global dilemma. Social distancing, means we spend more time within our homes than traveling, whether to work or for some “outdoor” time. The use of motor vehicles has decreased incredibly; the consumption of commodities is being used wisely rather than wasted; people prefer using recycled (i.e. reusable) products to decrease their land-fill garbage and save costs.

How is it encouraging recycling best practices?

The novel coronavirus, as terrifying as it has presented itself, is actually bringing out long- forgotten traits that we all have. I am referring particularly to self-sufficiency and preservation – both of which recycling is a prominent characteristic. I do expect recycling to not only increase during the Covid-19 pandemic, but become a staple in our everyday lives as a lesson.

The global pandemic and the impact it has had on our lifestyles, economies, and community structures and dependencies is very overwhelming. I am a strong believer, however, in our nation’s ability to adjust to circumstances, survive the worst, and come out wiser, more efficient, and better equipped. Recycling, a simple act that was sometimes undervalued, is now becoming a common-sense survival tactic, that will ultimately better the quality of our lives.

Is it possible that recycled materials can be contaminated with the virus?

Fear of transmission is certainly on everyone’s mind. While the virus is said to spread mainly through respiratory droplets, we have also heard that the virus can remain infectious for some time on various surfaces. Our industry’s precautions, prior to the Covid-19 outbreak, are generally aimed to protect staff from all the viruses and contaminants that they are exposed to. We promote the use of personal protection equipment, including face shields and non-puncture gloves, that we recommend our employees wash on a daily basis.

As mentioned earlier, our industry’s precautions, prior to the Covid-19 outbreak, are generally aimed to protect staff from all the viruses and contaminants that they are exposed to. We promote the use of personal protection equipment, including face shields and non-puncture gloves, that we recommend our employees wash on a daily basis.

Do you see the company expanding and including other facets of the industry in the future?

With Andover, we currently have the capacity to produce over 750,000 tons of cullet. That’s the largest in the United States. Our goal is to expand throughout the country, and really bringing the United States a global leader in the recycling industry. As mentioned earlier, we are looking to tackle other recyclable commodities, such as ferrous and non-ferrous metals, paper and even topsoil.

What percentage of glass found in waste is reusable?

Technically speaking all glass is recyclable; 100% of the product is recycled an infinite amount of times.

Yet, only 33% of waste glass is recycled in America. Considering the fact that over 10 million metric tons of lass is generated every year in America, that number is not very high. Whereas in Switzerland, Germany, and other European countries, about 90 percent of glass is recycled.

Delving deeper into the numbers, only 40 percent of glass thrown into single-stream recycling collections actually gets recycled.

While glass is completely recyclable, unfortunately, there are multiple reasons why it’s “downcycled”. For one, some facilities choose to crush the glass and use it as a landfill cover instead. This is cheaper than actually recycling the glass, or finding another cover material for landfills. This is done to control the offensive smells landfills give off, deter pests, etc. Unfortunately, downcycling prevents glass from being reused doesn’t help reduce omissions or reduce the use of raw materials.

On the opposite end of it, when glass is recycled, the benefits are enormous and wide-ranging. More specifically, estimates have shown that if 50 percent recycle rate would remove 2.2 million metric tons of CO2 from the environment. That’s the equivalent of removing CO2 emissions of nearly 400,000 cars every year. However, this would only happen assuming at least 50 percent of glass was recycled properly and used to make new glass.

How does recycling glass save energy?

Recycling glass saves 30% of the energy required when producing glass from raw materials (soda, ash, sand and limestone). Crushed glass, called cullet, melts at a lower temperature than the raw materials, which saves energy.

A standford study reported that one ton of recycled glass saves 42 Kwh of energy, 0.12 barrels of oil (5 gallons), 7.5 pounds of air pollutants from being released, and 2 cubic yards of landfill space.

Our plant in Jersey City in other words:

250,000 tons translates into

10,500,000 Kwh of energy

1.25 million gallons of oil

Nearly 1.88 million pounds of air pollutants (atmospheric emissions from melting activities; the combustion of fuel and the decomposition of raw materials during melting lead to the emission of CO2).

Our plant in Andover in other words:

750,000 tons translates into

31.5 million Kwh of energy

3.75 million gallons of oil

Nearly 5.6 million pounds of air pollutants (atmospheric emissions from melting activities; the combustion of fuel and the decomposition of raw materials during melting lead to the emission of CO2).

Is glass recycling more efficient than plastic?

Glass, because of weight, produces more emissions in transport than plastic, and costs more to transport. However, producing plastic bottles each year releases more greenhouse gas emissions than over a million cars on the road. Plastic takes about 500 years to disintegrate while glass takes 1M+. However, it’s important to note that plastic releases toxic chemicals into their surrounding environment as they break down, unlike glass. Glass is more durable, and hence more suitable for reuse. Further, glass can be quickly and easily cleaned and sterilized in boiling water, boosting its reusable properties. The best thing we can do is reduce our reliance on anything single-use; glass fits the bill in this sense, and is a favorite among zero-waste proponents because of the fact that it is 100% recyclable.